Drenched in the UK. Made in Germany.

The Ortlieb experience began just as I had imagined: in a pristine, cobbled Bavarian town square … where Martin (Sales Director) and Falko (Product Manager) treated Nils, Scot, Tom* and I to a traditional Franconian meal and Pils, or drei. We were in Heilsbronn – Ortlieb’s home, since 1997, when the growing bag-maker moved out to the south-western suburbs from central Nuremburg. Today (2019) they undertake all their development, manufacturing, marketing, and logistical operations under one roof here…

Like many of you, I have owned a pair of Ortlieb Classic panniers since my super early days of city commuting and first bike travels – they were the default panniers everyone used – they looked the part: waterproof and durable. But, having really gotten to know the brand’s bags and accessories through retailing and field-testing them on our Pannier.cc bikepacking exploits over the last five years, I still knew little-to-nothing about Ortlieb beyond their uber-utilitarian, uber-waterproof, uber-German image. I was eager to lift the lid – to hear more about their beginnings, their current operation, what makes them tick, and to meet some of the people behind the scenes. So, there I was, on Ortlieb’s home turf, munching my way through some Schäuferla whilst we discussed the next day’s visit to HQ and overnight bikepack adventure with Peter (PR) and Volker (Product Development)…

“Like the swords in mythology that make their bearers immortal, Ortlieb bags make their owners untouchable to any kind of rain”

Before we set off, there are a few things you should know:

1. Hartmut Ortlieb is an actual guy. Trust me, I’ve seen his locker. Until recently, I’d just assumed ‘Ortlieb’ was a German word for something technical – sounds it, right? Just me? Anyway, Hartmut Ortlieb is the founder of Ortlieb…

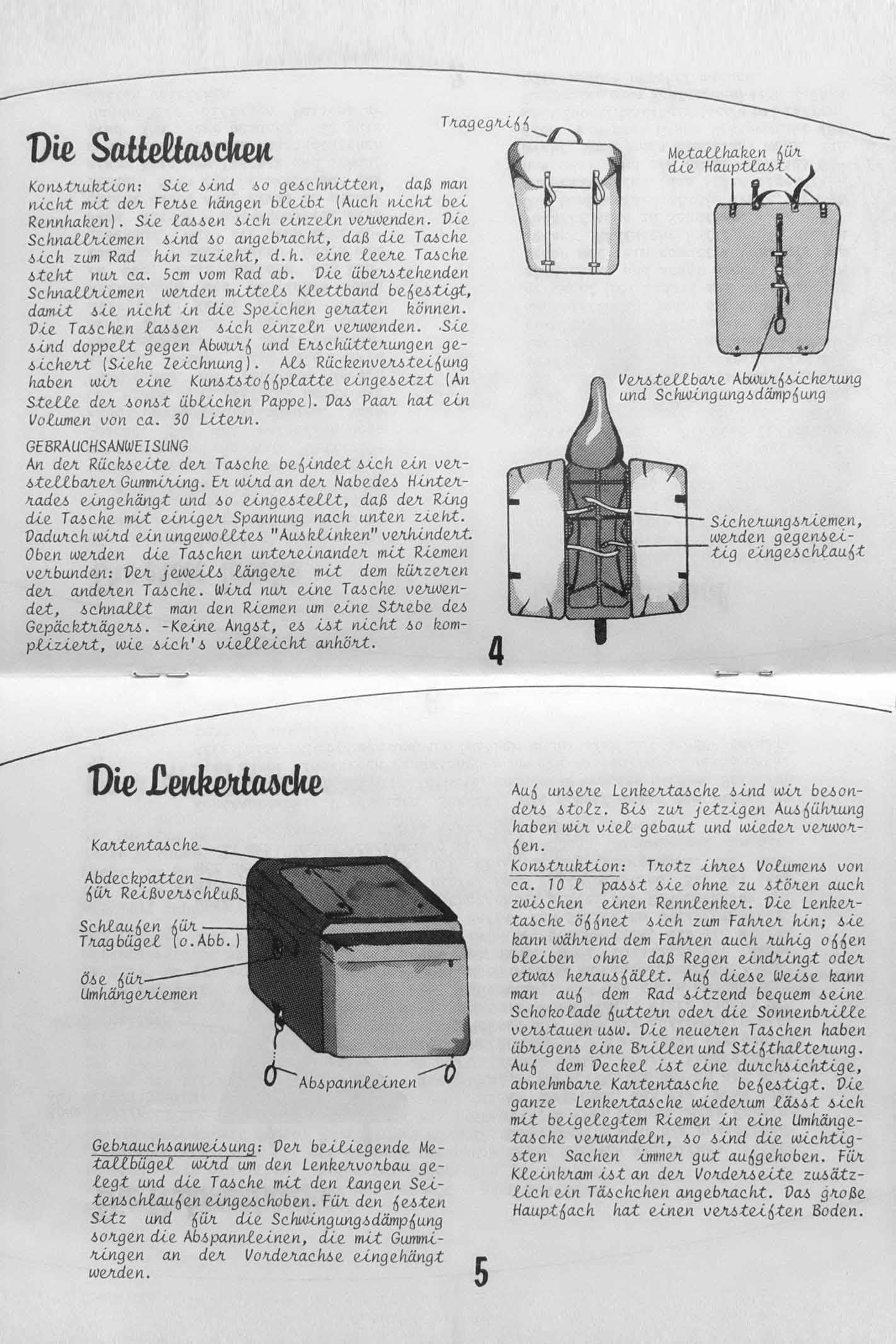

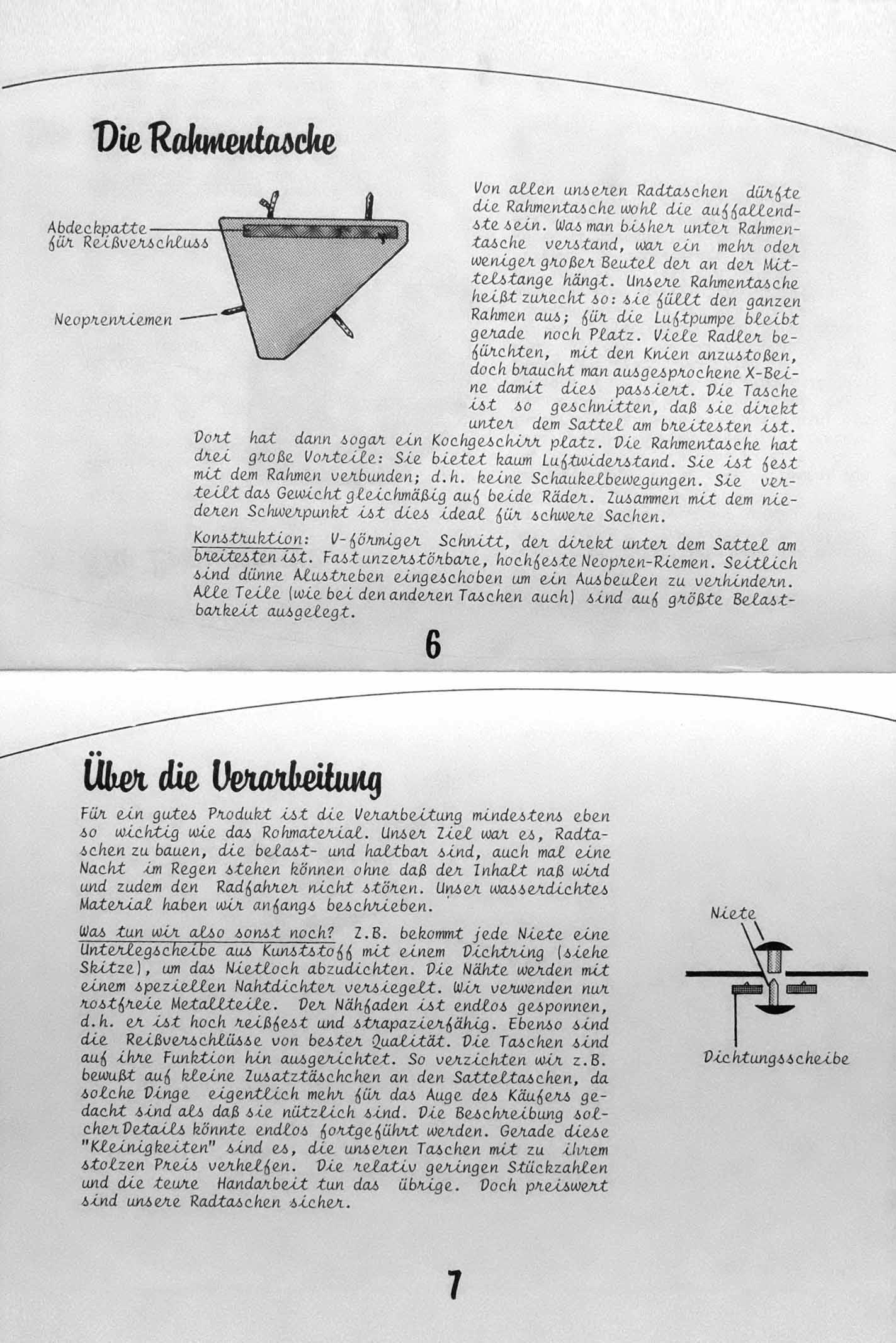

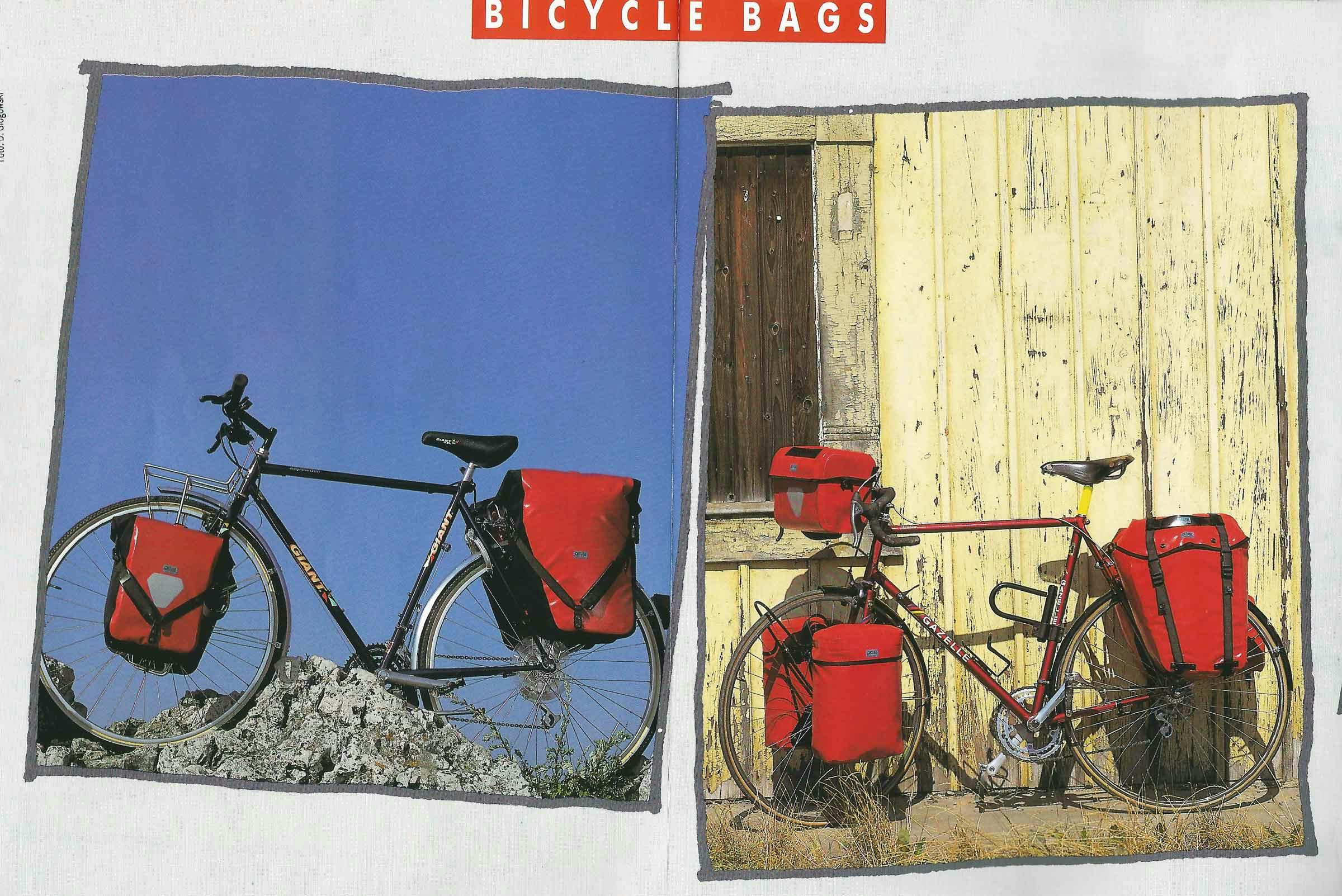

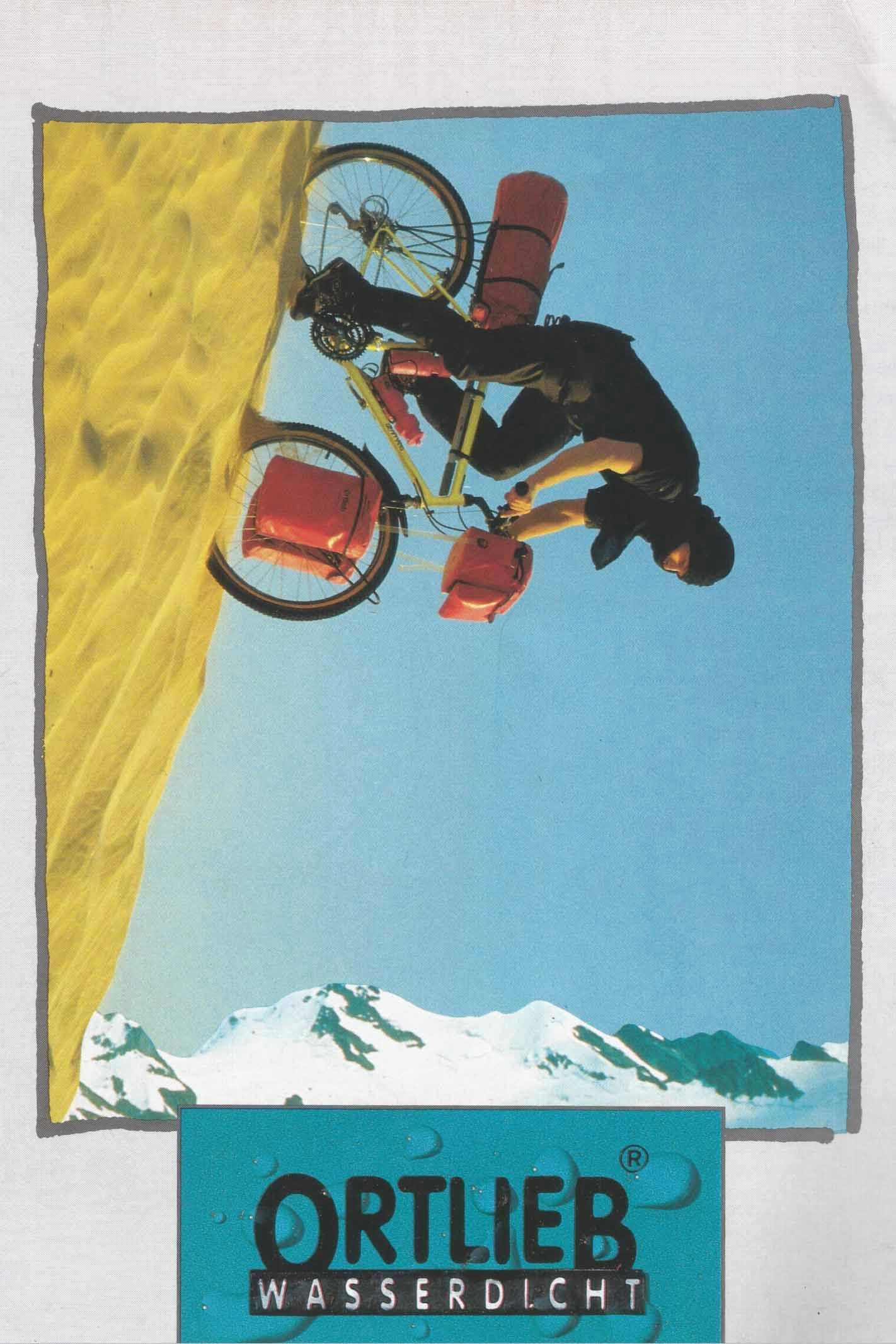

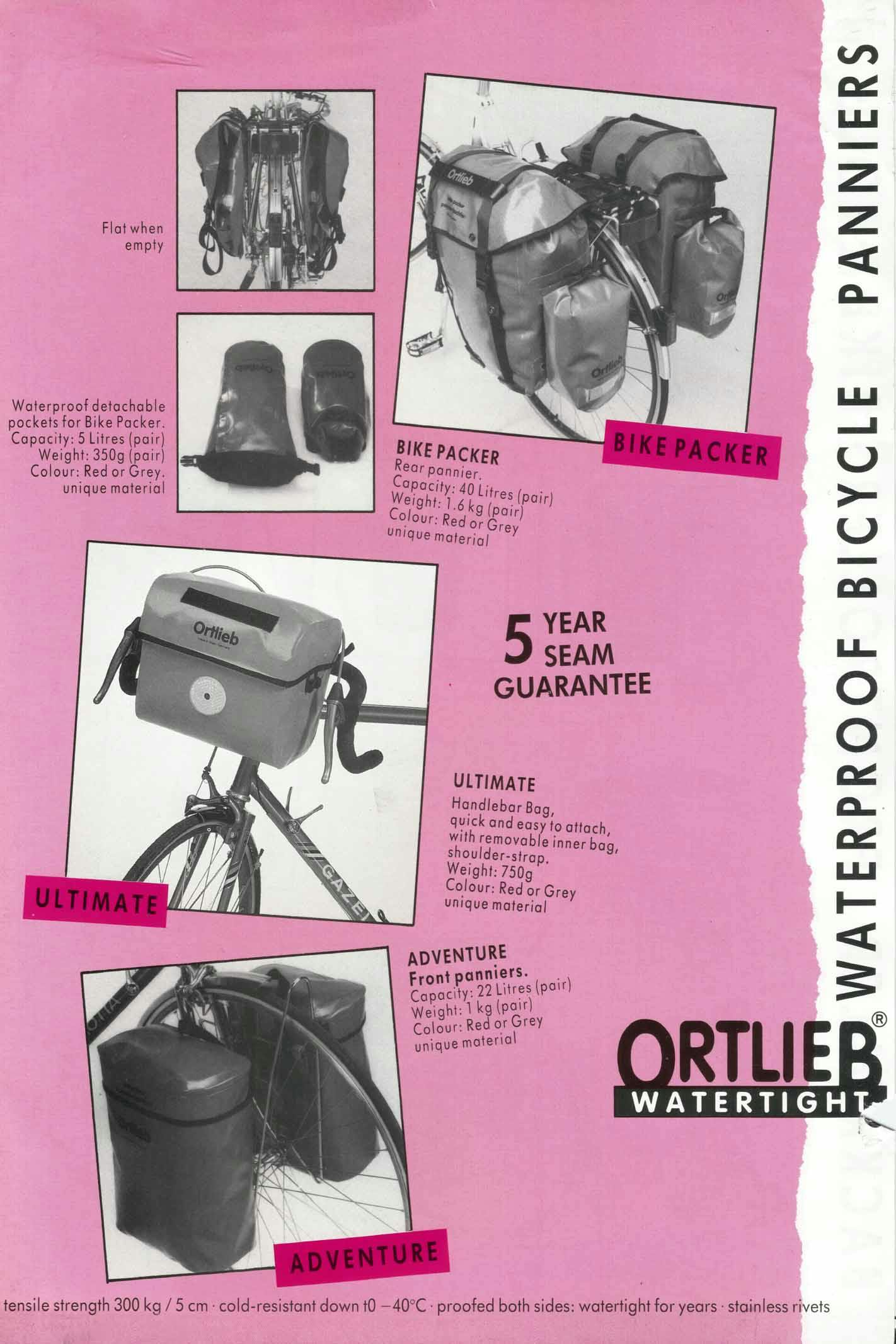

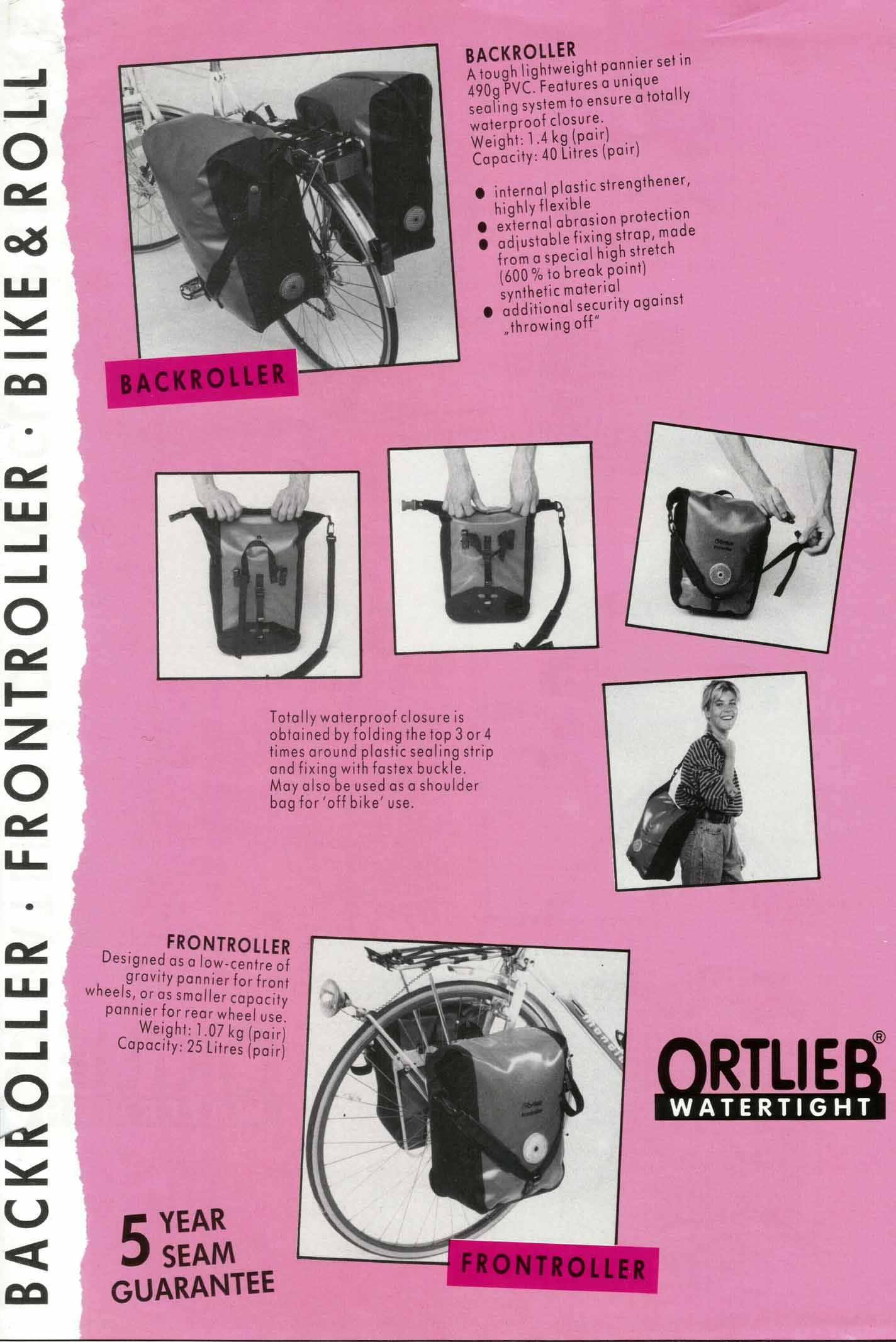

2. Ortlieb were using the terms ‘bikepacking’ and ‘bikepacker’ before I was even born. Check out their original luggage from the mid 80’s…

3. Ortlieb’s waterproofing method (high-frequency ‘3D’ welding) is uber-secret, so don’t expect to see any photos of this area of the factory, or most of the other areas of the factory processes at all. I’d like to say I’d be done for espionage, but I wasn’t even allowed anywhere near these areas…

4. Ortlieb’s custom-made machinery is also uber-secret, so don’t expect to see any photos of the big room where they design, build and service this stuff, or any of the machines in use on the factory floor. I’d like to say I’d be done for espionage, but….

5. In 2019 and beyond, Ortlieb are our partners for our bikepacking bag needs on all Pannier tours and events: if you hire bags, they will be Ortlieb. Hopefully, you’ll understand why we’ve made that choice from this Journal piece.

6. The end of October is peak Pumpkin Season in Ortlieb’s Franconian backlands…

Hartmut Ortlieb [p.]

Ortlieb Founder

“…Southern England in the spring of 1981. Continuous rain falls on the rolling hilly landscape. In the middle of it all is a young cyclist with a curly mop of hair and a packed bike. He seems annoyed…

…he sees a truck pass by. The constant rain patters on his tarpaulin, but the cargo remains dry. This event marks the birth of the waterproof ORTLIEB panniers…”

I was excited to meet Hartmut; the guy behind the brand so synonymous with panniers. Interested to ask about Ortlieb’s beginnings – his UK bike tour and moment when, drenched by the side of the road, he realised a) how ideal a set of 100% waterproof bags would be and b) how a lorry tarp pack might be the best way to do it. However, my hopes were quickly hailed upon when, over our first pils, Martin told us Hartmut would not be available during our visit. Gutted. I kind-of-knew it. His 1980’s “mop of curly hair” would have to live on in photos and my mind.

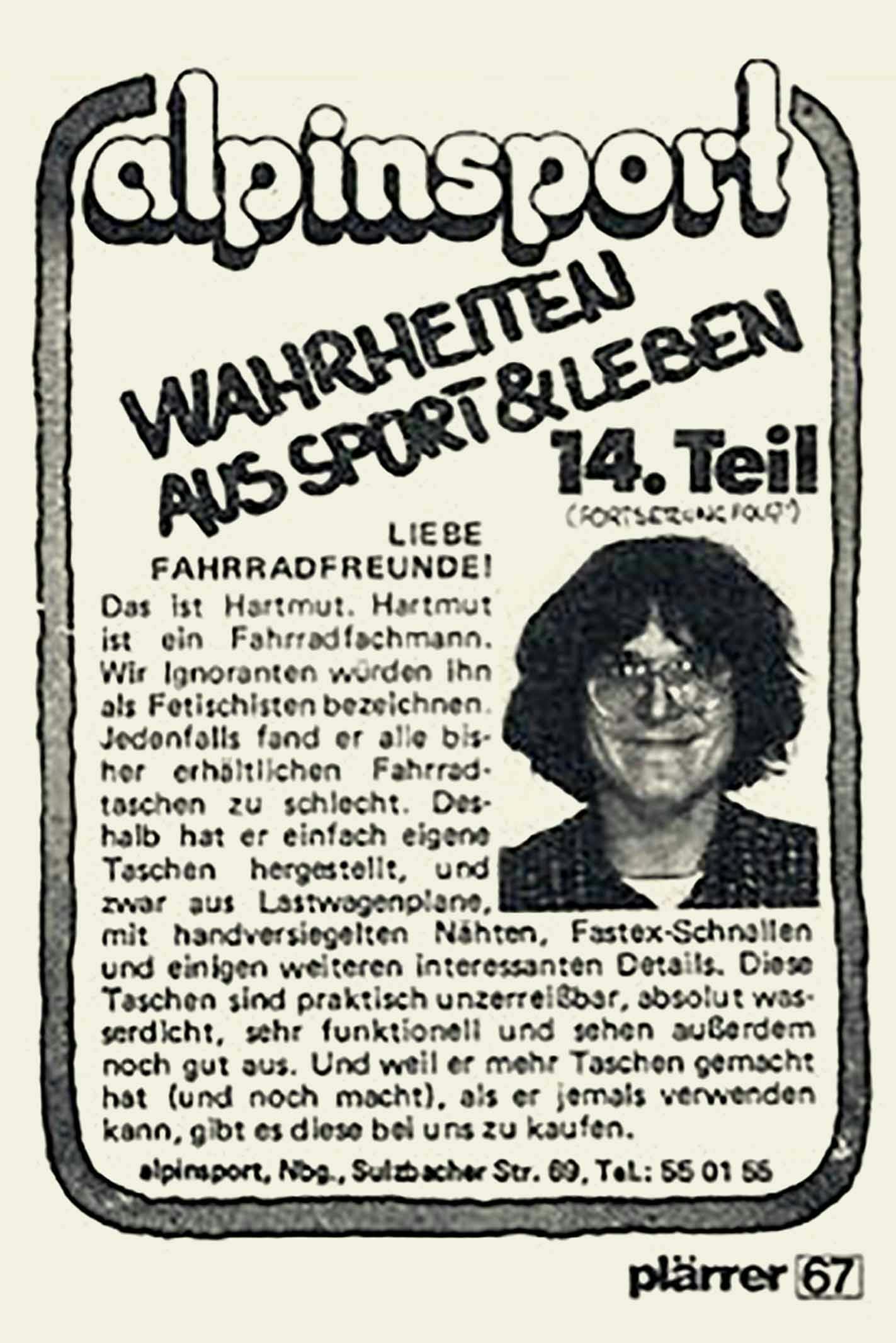

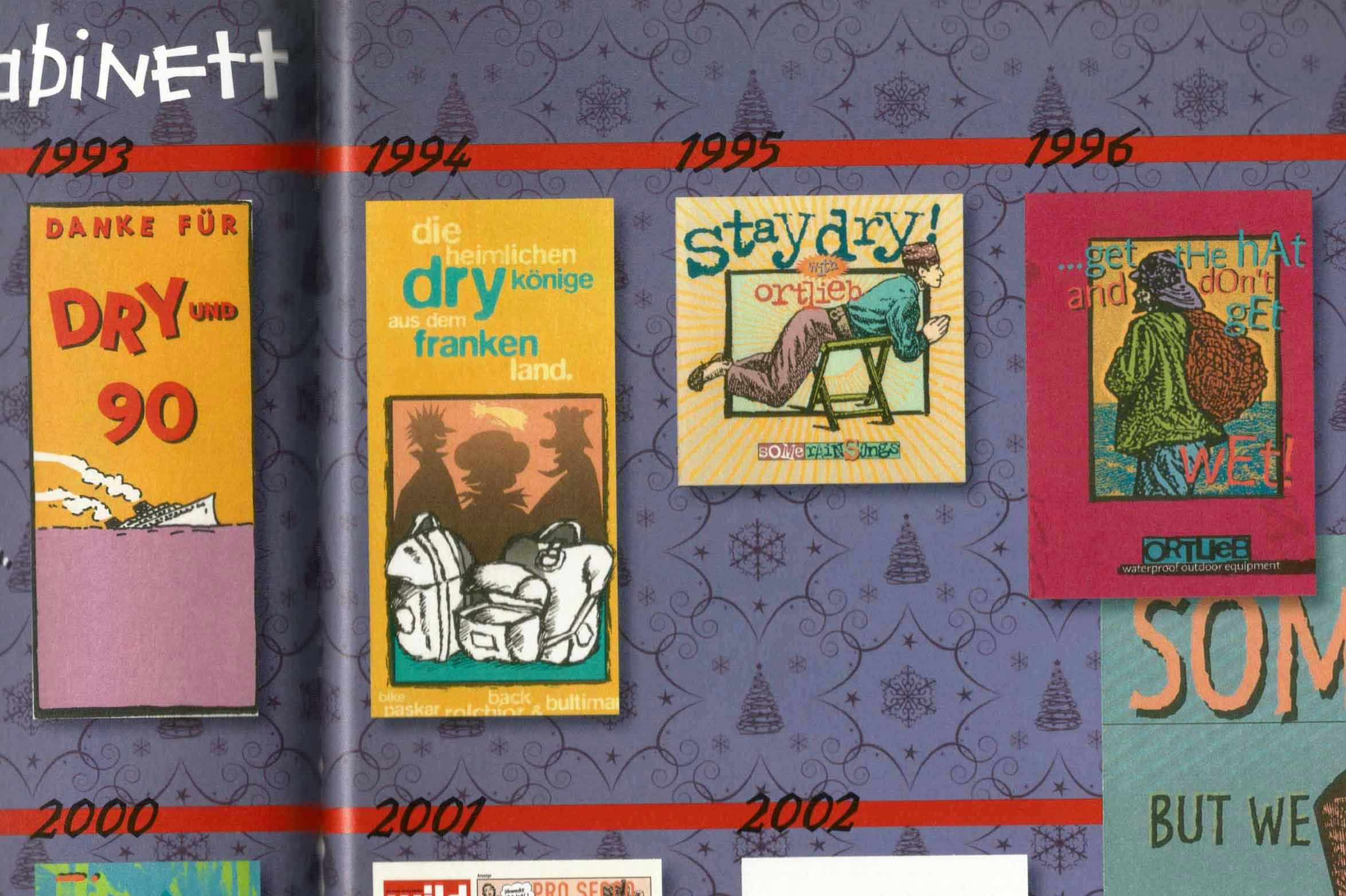

…anyway, now in his 50’s, Hartmut is back running the tech and production side of his company alongside new CEO Jürgen Siegwarth, who joined recently in the wake of Wolfgang Paulus’ retirement after 25 years at the helm. According to the first ever Ortlieb advert (below), not only does it look like he did all his copywriting in the third-person, but Hartmut was a “Fahrradfachman” (Bicycle Specialist):

“DEAR BIKE FRIENDS!

This is Hartmut. Hartmut is a bicycle specialist. Us ignorant folk were calling him a fetishist – he could not find a bicycle bag available that was good enough. That’s why he just made his own bags out of truck tarpaulins with hand-sealed seams, buckles and some more interesting welded details. These bags are virtually unbreakable, totally waterproof, very functional and look great. And because he has made (and still does) more bags than he can ever use, these are available for purchase…”

After returning home from his UK trip, at the age of 18, Hartmut begun tinkering with packing boxes made from this lorry tarp material – sewn together at home on his folks’ sewing machine. He, apparently, used whatever webbing straps and hooks he could get hold of from the hardware store to close the ‘lid’ and fix the packs to his bike rack. A typical Franconian guy, he was into his cycling and outdoor pursuits, and in a story similar to many outdoor brands beginnings, he started making his early bags and prototypes for himself and pals to go on bicycle and climbing trips. Basic handlebar bags followed the rear panniers and soon enough “friends, acquaintances and dealers showed interest in the functional bags” to the extent that “demand soon overburdened the one-man operation”.

Hartmut, along with his seemingly unsung** friend Peter Wittwer (who passed away last year) then bought a couple of their own sewing machines, pictured together above, and started making “more virtually unbreakable, very functional bags than they could ever use”. Soon, family members and friends were brought into the fold and in 1982, Ortlieb was founded.

Sounds like Ortlieb and Wittwer were akin to the Chouinard and Frost, of the bike bag world…

“In 1981, we began production of quality equipment for the outdoor sector, for people who are always a little out of the ordinary, for whom freedom from everyday routine and living close to nature are of the highest importance…The critical demands of this target group form the framework for our product development.”

So, let’s track back to 1982…

Hartmut, still a teenager, had been making his tarp panniers for a year or so – and was slowly increasing his Nuremburg Garage team to cope with demand. “Their first product brochure (below) presents the small, manageable assortment of bags” – including what doesn’t look dissimilar to their 2018 released bikepacking frame bag – which Hartmut presented at their first trade fair – in a dark niche below an escalator, very much out of the spotlight. However, “the general advertising strategy of ‘word of mouth’ was working overwhelmingly”; it seemed the product was good…

For Hartmut, waterproofing and durability was the big thing and punching sharp needles through fabric wasn’t cutting it for him. According to the early Ortlieb literature: “how do you manufacture a lightweight bike bag that is completely waterproof no matter what the weather?” was the question Hartmut set himself as a brief. So, they quickly began researching ways of welding the tarps / PVC materials together – testing out Radio Frequency (RF) Welding. However, even this was not adequate for Hartmut; not adequate for Ortlieb – the burgeoning bag-makers. They went on to develop and test a High Frequency (‘3D’) Welding technique, in some kind of late C20th space-style waterproofing race which, to this day, remains uber-top-secret. I wish I could tell you more about the process, but they guard it not even with non-disclosure agreements, but by the closure of most of the factory to outsiders. One thing they say to this day is that “without Ortlieb, there would be no high-frequency welding; without this quality of welding, there would be no Ortlieb”…

Since 1982, it has been a constant working process of improving and solving problems with the products. Hartmut actually travelling by bike and spending time in the Outdoors was key; he was an active user and tester of his own products. According to the early product literature – “high frequency was the magic word” and once Ortlieb bags were welded to be 100% Waterproof the first milestone had been set. “The next one followed immediately: the roll closure” instead of the lid system. This made the bags even more water and dust-resistant, and it is a system they still use today on all their bags, not just panniers. Next up was developing the first self-locking Quick-Lock (QL) fastening system, given the hardware stores couldn’t keep up with Hartmut’s needs and quantities. The QL1 System was their first mounting system for bike panniers – developed to allow easy single-handed mounting and removal of panniers from a bike rack. The automatically closing hooks replaced the complicated attachments with straps and buckles, which were seen as slow and unreliable. Thousands of the indestructible mounting QL1 system have now been used for decades on classic pannier models such as Back-Rollers and Bike-Packers, and are still in use today. Anyone with a set of classic panniers, and indeed panniers from a few other brands, will likely know their QL2.1 system…

…“meanwhile, the company had grown to 20 staff, including ‘Mother Ortlieb’”

“Long ago the advertising strategists discovered the off-road sporting adventure type … fashionable design overtook lasting reliability as a sales argument. But we remain true to our ideals…”

ORTLIEB MILESTONES

– Hartmut’s Lorry Tarp ‘Pack’ Panniers

– Welded Waterproof Seams

– Roll-Top Closure

– QL Hook and Fixing Systems

– ‘Back Roller’ Classics

– ‘Packman’ Messenger Bags

– Material Miles (70%+ from Germany)

– Bikepacking Bags

– ̷M̷y̷ ̷V̷i̷s̷i̷t̷ ̷(̷2̷0̷1̷8̷)̷

– …Recyclable/Biodegradable Materials (2025)

“Since I mounted the first pair Ortliebs on the bike, I have learned to love the rain: no matter if monsoon rains or the finest Scottish “drizzle”, whether in the middle of August, at Paris-Brest-Paris or at the Landmark Trophy, I am immune to the rain…

…rain has its charm; no matter how wet the ride may be, in the evening you open the closure of your Ortlieb bag, roll up the ‘tarpaulin’ and take out a dry and fluffy towel, dry yourself, put on some fresh, guaranteed dry clothes and think, “this was a great tour”. To date, in my head, I have not bought or sold a single Ortlieb bag – no – I see it more as buying dry, comfortable kit.” Hartmut

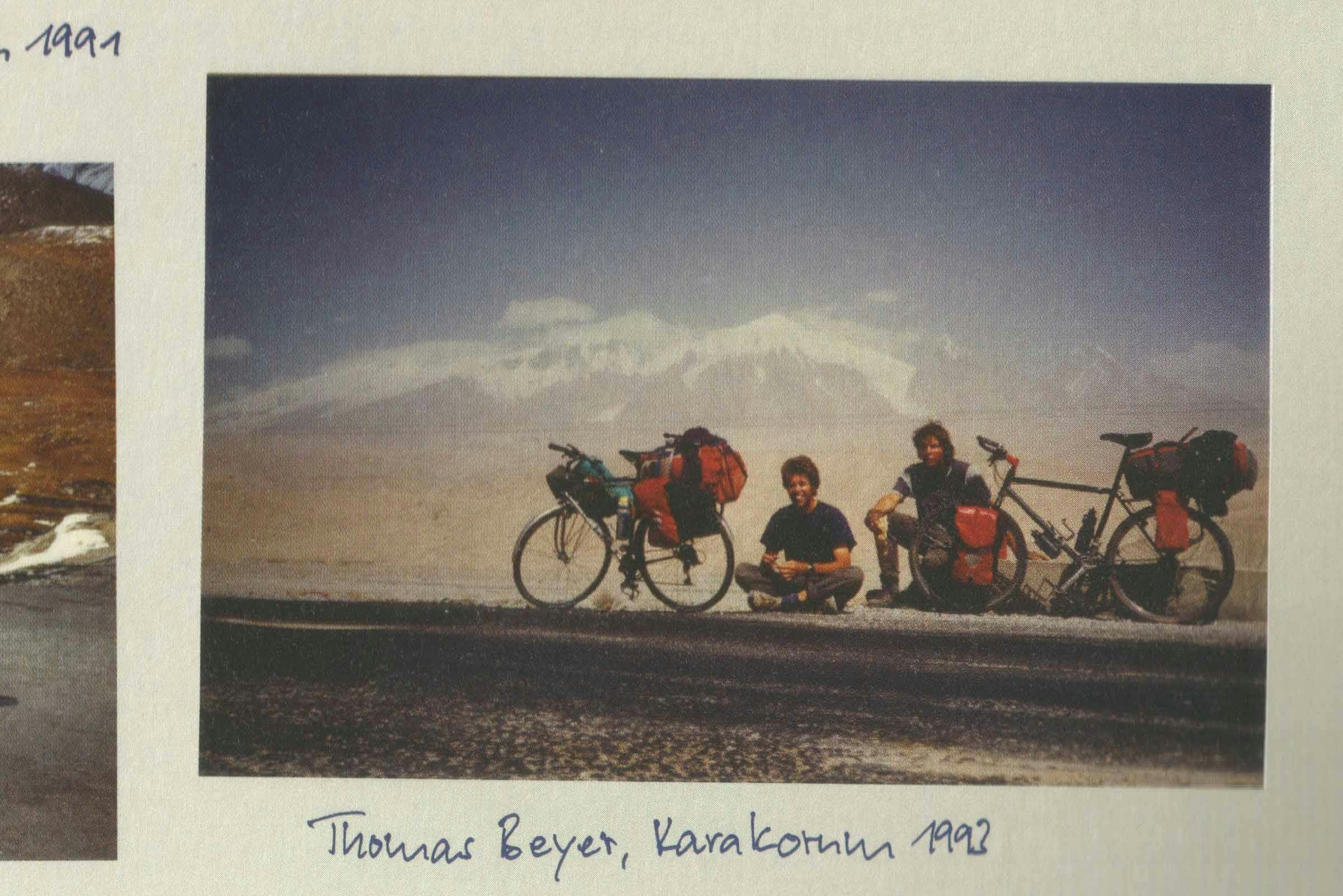

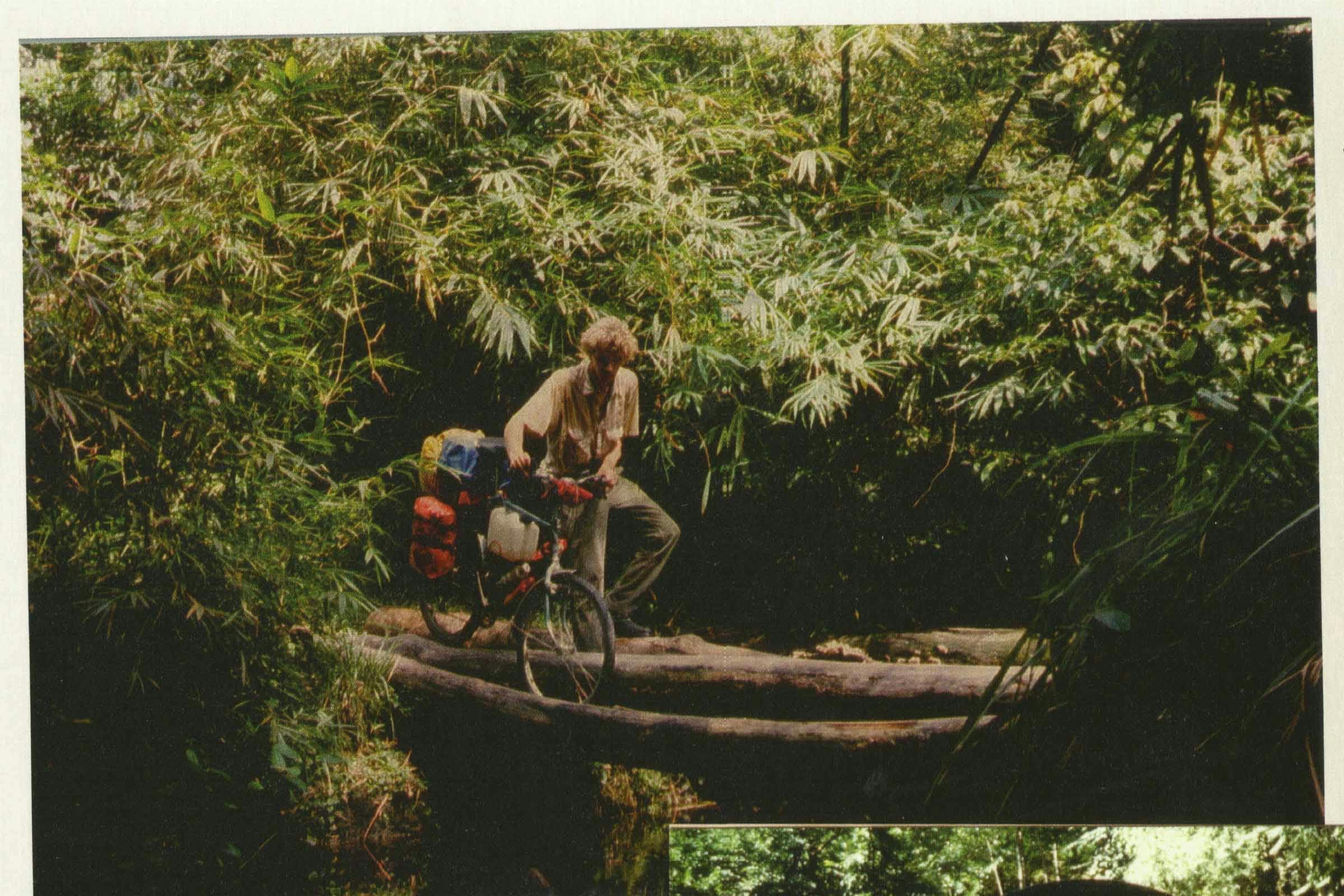

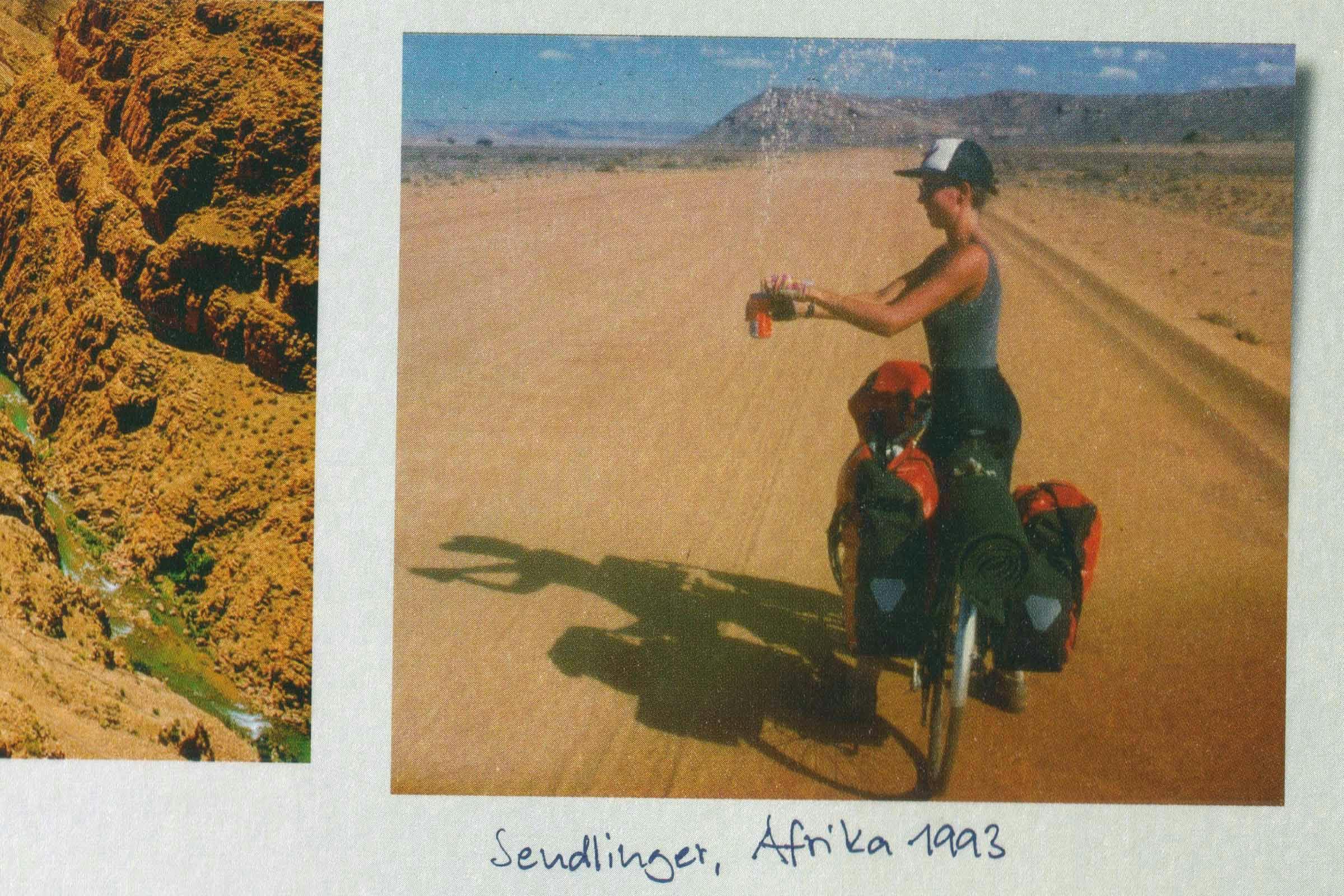

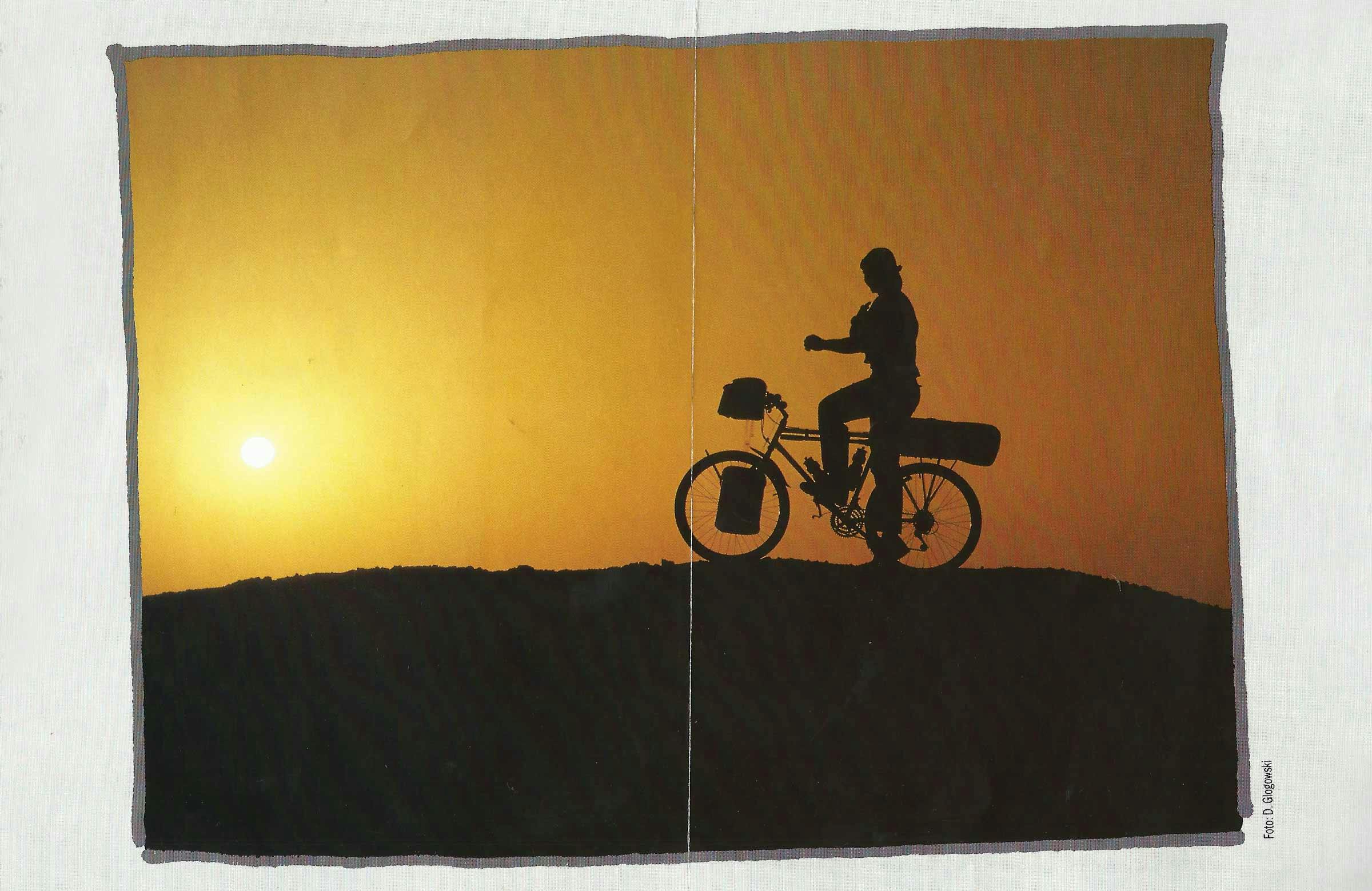

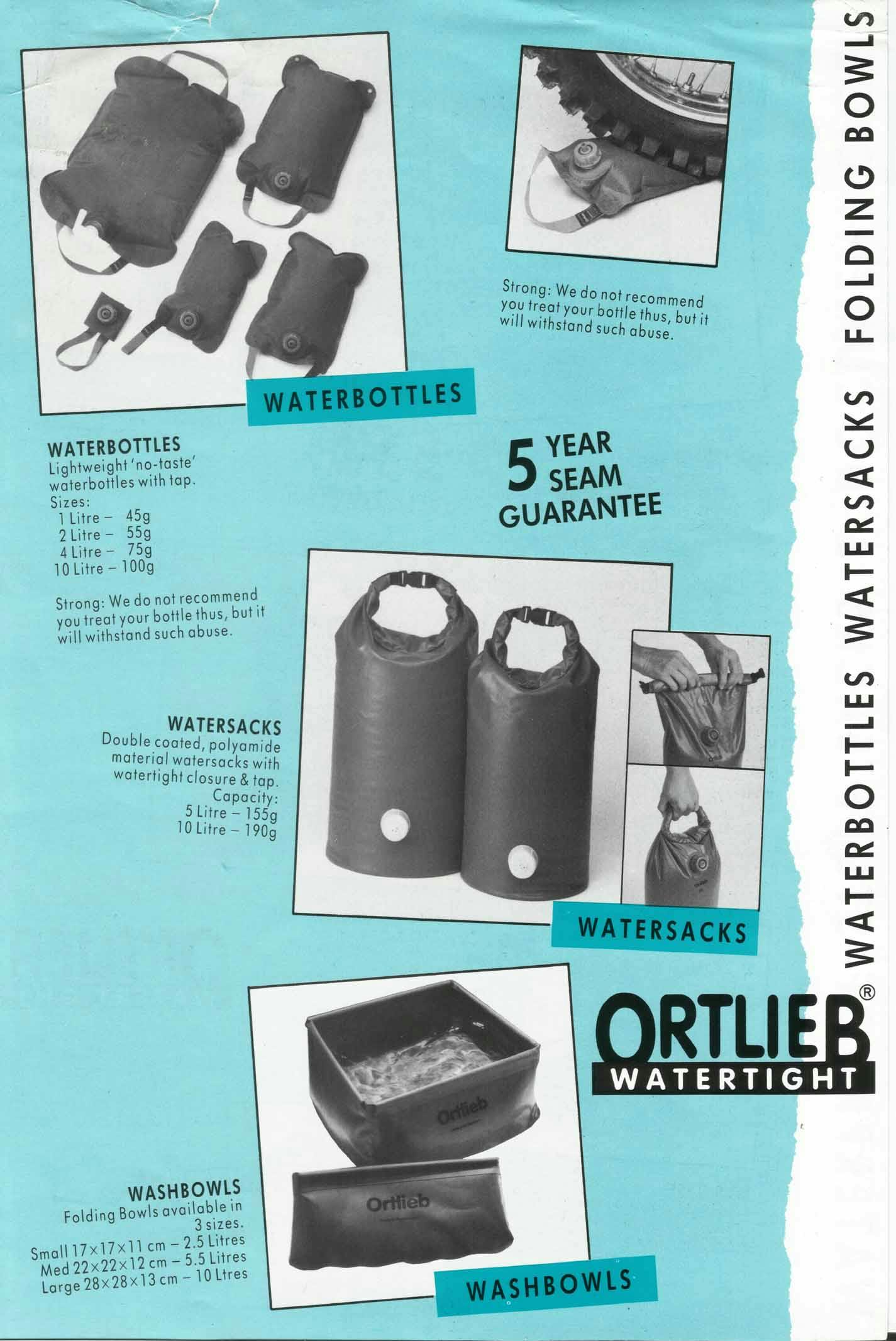

By the end of the 80’s, Ortlieb were making a few thousand panniers per year and had started manufacturing other products like drybags, in Nuremburg. Throughout the 80’s, into the 90’s these Ortlieb bags were heading off on round-the-world trips and to far-flung destinations on loaded touring bikes. Despite “advertising strategists discovering the off-road sporting adventure type … and fashionable design overtaking lasting reliability” Ortlieb, importantly, remained true to their ideals”:

1. Material, manufacture and design must meet the requirements – without compromise. Much value is placed on weight saving without succumbing to a light-weight fetishism at the cost of durability.

2. In addition to this, the product must look appealing, but not so that is unfashionable the very next day.

…and so their bags were used by cyclists on four continents for their trusted name – “not mass-produced goods, but a measure of quality, made in Germany”

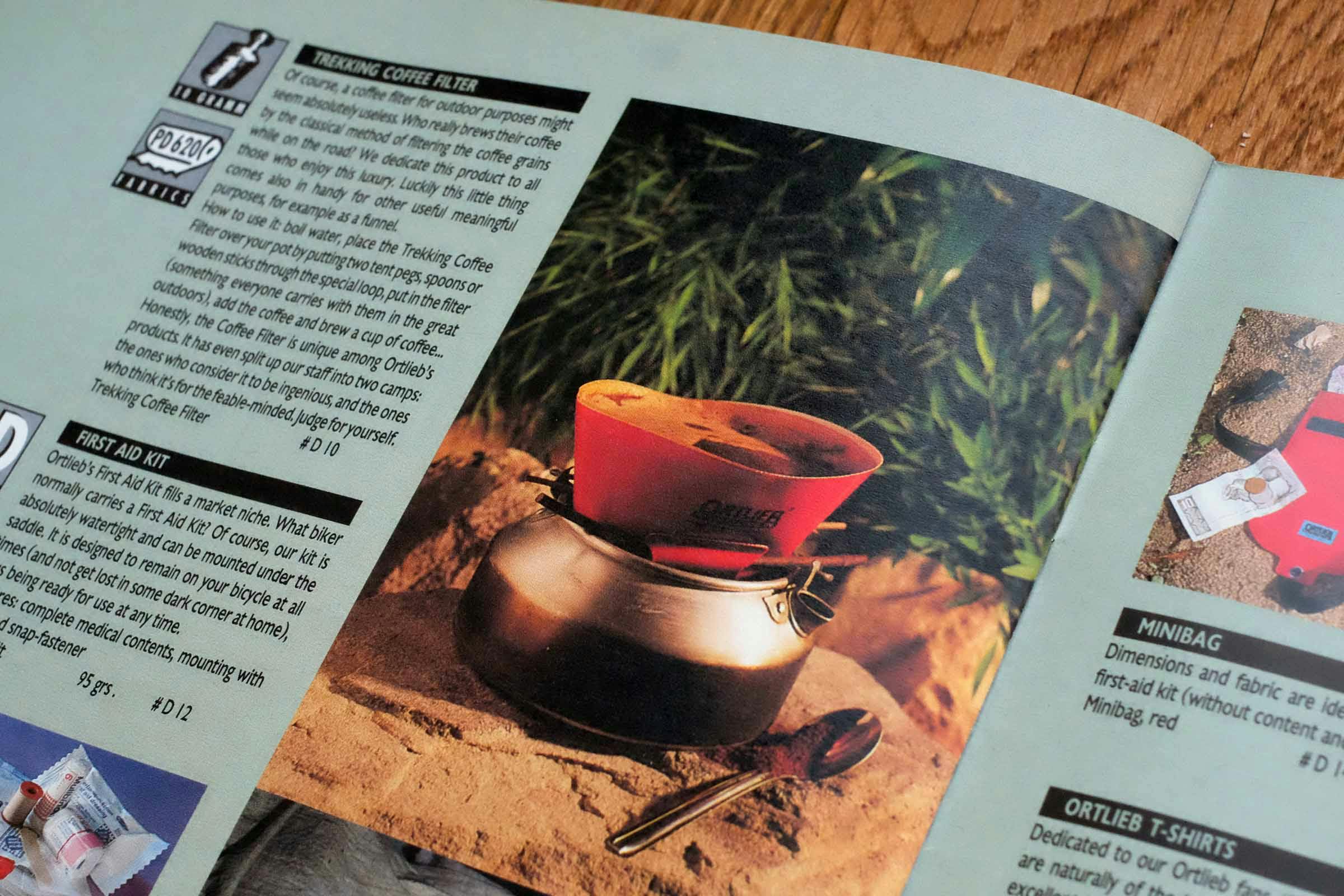

“Of course, a coffee filter for outdoor purposes might seem absolutely useless … The Ortlieb Coffee Filter has split our staff into two camps: the ones who consider it ingenious, and the ones who think it’s for the feeble minded. Judge for yourself…”

“Without Ortlieb, there would be no high-frequency welding; without this quality of welding, there would be no Ortlieb”…

…by the Mid-90’s, demand for watertight messenger bags was growing too, and so Ortlieb developed and launched their first waterproof backpack – the “Packman” – with an ergonomic carrying system. With this whole range of product, and demand, “the capacity in downtown Nuremberg was finally bursting at the seams and the 60-strong workforce moved to the new 2,200sqm company building in Heilsbronn”, in 1997…

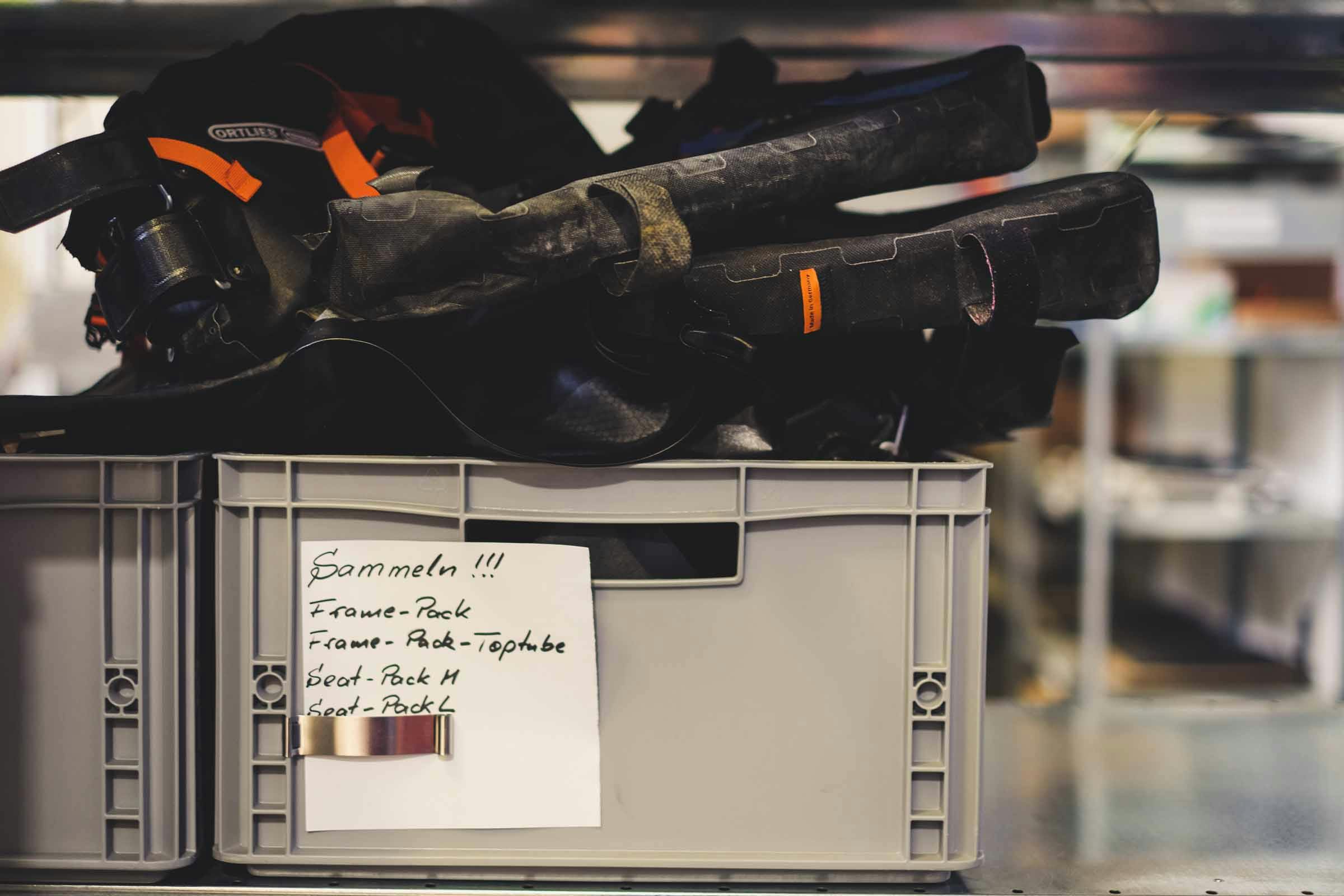

Today (2019) Ortlieb are still in the same location, now with 235 staff and 14,000sqm of space. Panniers remain a huge part of their business, but, as you’ll know, their bags and accessories are also now well established in the general Outdoor industry. An intriguing part, from my perspective, was to see the Ortlieb bikepacking bag range piquing their interest, product development time and production lines. Again, all made and repairable in Germany, to Ortlieb’s trusted standards. They were unable to provide numbers and production statistics on their current bags, and the % change they’ve seen the bikepacking range take from the pannier market, of course…

…”the history, traditions and practices that exist from the past and continue to be important”: excellent craftmanship; a passion for high quality, durable products; Made in Germany; 100% Waterproof … is what Ortlieb have stood for since 1982

I was being watched…

…at least that’s what it felt like wandering Ortlieb’s fantastic office, communal canteen and shared courtyard spaces. No more so than in the factory … I was a spy, after all***. As I mentioned earlier, there was a line: a literal yellow line, painted on the floor, that I wasn’t allowed outside of incase of glimpsing any of the secret factory processes or the big (amazing sounding) area where they make, test and service all their proprietary machinery. This pretty much ruled everything out except for material testing, storage, cutting, and repairs so don’t expect an in-depth Ortlieb manufacturing processes essay or photo series(!)

Instead, I thought it would be cool to highlight the things that stood out most during our tour with Peter:

>> Ortlieb’s processes clearly define their product and who they are as a brand. Peter pointed out that it is Ortlieb’s speed of production and quality of their proprietary high-frequency welding techniques that separate them from competitors. It’s fair enough that they want to keep them uber-secret.

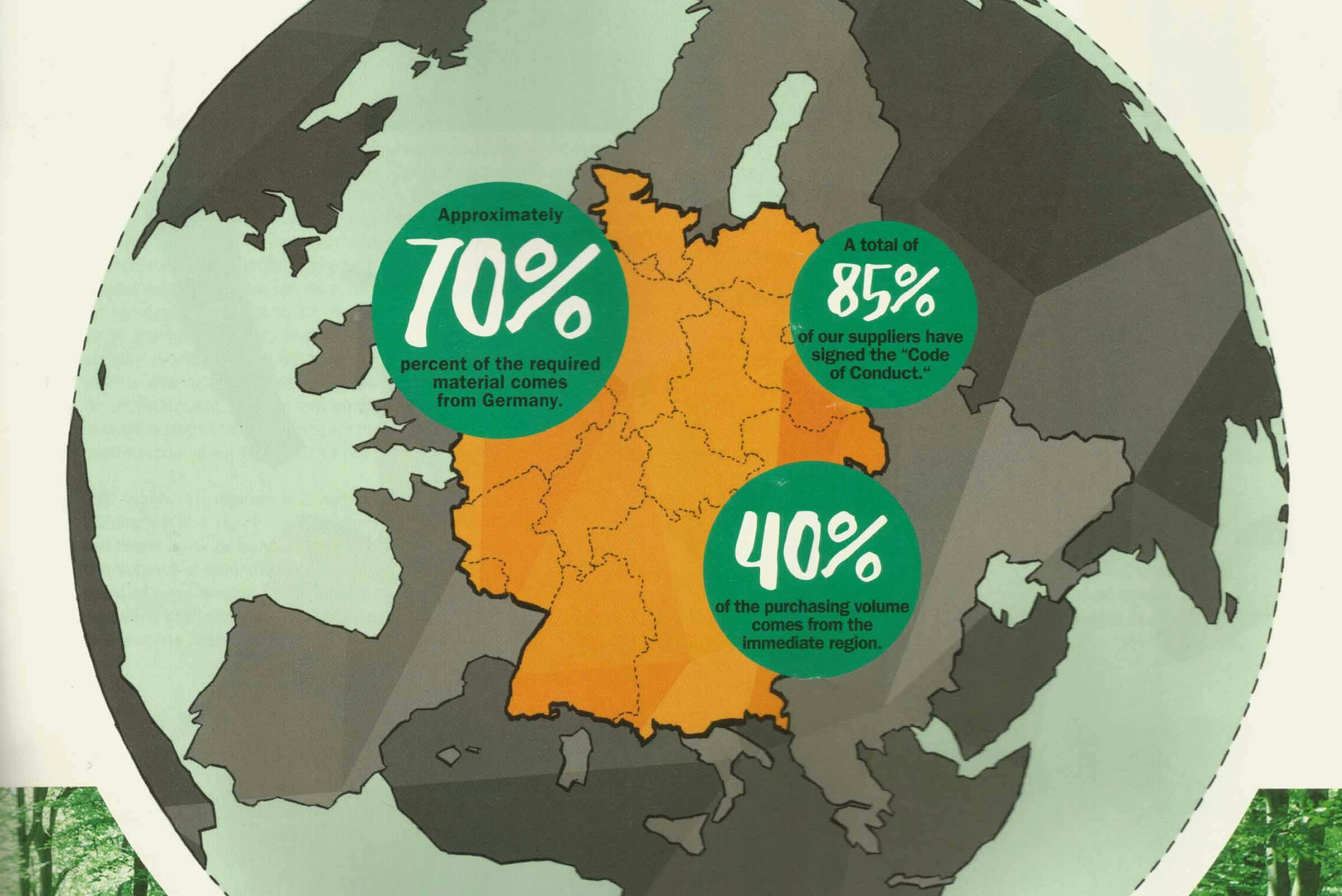

>> Heilsbronn is home. Ortlieb still make 100% of their products under one roof here, in Germany, from materials 70%+ sourced in Germany. The place is impressive and unsurprisingly efficient – all teams from product development, to sales, to manufacturing, to marketing are within the same walls.

>> Since 2013, Ortlieb have had a rather forward-looking Sustainability Framework in place. As of 2017, their facilities are supplied exclusively with renewable electricity – hydro and 33% from their own photovoltaics. Carbon emissions from their natural gas use is compensated at 100%. There’s a bit more detail on their material miles, below…

>> Tizip, another company founded by Hartmut, shares some of the building with Ortlieb. They make zips – 100% waterproof and 100% made in Germany, of course. Hartmut has some serious principles. All the Ortlieb zippers are made by Tizip.

“There is a company in Germany that manufactures some of the finest outdoors equipment and doesn’t give a hoot about the widespread opinion that production is only possible in labour-cheap countries. Ortlieb has proven this to be wrong by following these key principles:

– functional product

– excellent quality and reliability

– value for money

– ignoring fashion trends”

It all starts with the fabric…

In the bag manufacturing version of Food Miles, Ortlieb place a big emphasis on their Material Miles: over 70% of purchasing volume comes from within Germany; 40% of which is from their immediate region. Currently, all Ortlieb plastics are produced in Europe, whilst their softeners come from within Germany. One of the big associations will be Ortlieb & PVC, but since 1993 they have systematically analysed any ecological weak points in their production and, improved a great deal – now using PVC-free, coated fabrics and Cordura (their ‘Plus’ pannier range, for example) – with the aim of recyclable, biodegradable materials and zero-production waste by 2025. They already offer durable, long-lasting, repairable products, but they are aware that the disposal of plastics from the manufacturing and retired products present an ecological flaw – their long service life and repairability are important for this reason.

Once at the factory, the fabrics are batch sample tested in two ways:

1/ Pulling and folding (stress) tests. Every material batch is tested – folded 100,000 times to check wear-and-tear. In fact, the welded material on the finished product is supposedly twice as strong as the fabric itself.

2/ Waterproof testing. We managed to watch the guys test a piece of Cordura under intense pressure from the PFAFF machine.

One sample from each of the finished batches of bags are also waterproof tested – rotated like a giro under water jets for 1.5 hours!

Production wise, each bag is made in big batches, so fabric is cut down from the roll to rough size by laser/water jets (2000PSI), and then by each of the bag pattern-cutters, which the workers pick from amazing old-age forge-style vertical shelving. Out of the 500+ Ortlieb’s SKUs, labels like “Back Roller” and “Sport F̶r̶o̶n̶t̶ Roller” stood out.

We wandered past as the workers pneumatically clamped down on a series of Ultimate 6 Handlebar Bag cutters. Ortlieb are aware that it is difficult to make use of material offcuts – they are minimised in the first place, but then any excess material is sent to ‘Fahhrad Berlin’, an organisation who make small products from them. By 2025, they aim to have zero-production waste…

At this point, the bags are then shaped, welded and finished. But, this was beyond the yellow line…

ALLES WEIDER GUT!

Everything is alright again!

Watching Anke at her Repairs Station was like clockwork: bag out, notes read, check for defects, warm the heatgun, prepare the patches (matching the bag material), heat weld patches, and then … the all-important ‘daylight’ test, as she calls it, holding the bags to the sky to test whether a good job has been done or not. Repeat…

There are currently three staff carrying out repairs, each with different lengths of service. Martina has worked at Ortlieb for 18 years, Monica for 20 years (who also helps out with prototyping) and Anke (pictured below) who has worked at Ortlieb a few years now. Upon our arrival, Anke was just about to repair these traveller’s panniers which had suffered slight abrasion on the main wall, and needed the old mounting system switching out to the updated QL system…

For me, this side of Ortlieb’s offering was the most engaging part of the factory visit. In my mind, a product’s longevity is the integral requirement of a sustainable product. Durability has been a big part of the brand’s heritage since, like, forever, and seeing Anke repair and upgrade an old set of well-travelled Back Roller Classics sung of longevity, sustainability and duty: the hallmarks of an Ortlieb bag. I’m sure all Ortlieb bags can tell a tale, or two…

So, not only are Ortlieb shouting about making the most durable bags they can, but that they’ll keep your bags waterproof and functioning for as long as you need them too. For, as Hartmut says, you are not investing in an Ortlieb bag, rather a lifetime of safe, dry and comfortable kit…

Tom, from Ortlieb UK, was in Heilsbronn with us (pictured here) to be trained on the welding equipment and repairs. So, you’ll be pleased to know that if you send your Ortlieb bags in for repairs or upgrades in the UK, it is more than likely this guy will be working on them for you. If he can mend a bag as well as he can serve tea by a tarn, we’re all onto a winner…

Now, I’m a big advocate for repairing kit – anyone that has looked closely at any of my insulation jackets will know that they’ve seen the Patagonia Worn Wear van a fair few times. Once I’d seen the Ortlieb Kundenservice in action, this benefit alone was enough to work with Ortlieb as the bikepacking bag provider for our Pannier Tours & Events – their bags are not only functional, but long-lasting, and can be fixed easily if and when needed…

The ‘daylight’ test is the final step in the repair process. Tom is now a pro…

It was autumn … and the height of pumpkin season in the farmed and forested Franconian backlands.

An overnight adventure from Ortlieb HQ had always been part of the plan for Scot, Nils and I, once we’d spent time at the factory and glimpsed behind the scenes. Our guides – Peter and Volker – snuck us out at 16.00 to pack our loaner Bombtrack bikes for the out-and-back ride to a local co-operative owned hut that Peter knew of, around 50km away.

The October days were still long; not a rain drop in sight; not a ford or river to be crossed; no chance of anything getting wet. But, in fairness I didn’t really need to come here and ride in the wet to justify Ortlieb’s reputation for making 100% waterproof and practical bags. Like Hartmut back in 1981, I’d tested Ortlieb’s waterproofness through torrential rain *enough* on numerous UK bikepacking trips to know that they did what they say on the PU Coated Nylon. The sunshine and big empty skies made for a crackin’ few hours of riding. No big landscapes around this part of Germany, but plenty of fun farm and forest tracks to enjoy and enough distance for a challenging evening out…

Like all good hosts, Peter and Volker had packed a wood saw, selection of lovely Bavarian Beers, the ingredients for a rather special meat & veggie barbecue (including local ‘Drei im Weckla’ hot dogs) and … a Bialetti stovetop. Men after my own heart…

Nils lit the fire as the sun set a big, bright orange over the small village horizon, and we all sat around cooking over drinks and discussions about bikes, and future trip plans. After a long day and some decent kms in the legs, the five of us were more than happy to retire into the hut, and the warmth and comfort of our sleeping bags as the embers just about stopped glowing in the light breeze. Ready to drift off and dream about welding, no doubt. It would be an early start tomorrow – Peter and Volker needed to be back at Ortlieb HQ…

Drei im weckla [n.]

“three in a bun”

Franconian hot dog (three Nuremberger sausages in a bun)

The guys guided us back at a pace far too quick for the 15KPH Club – retracing our tracks from yesterday and mirroring our tread marks in the dusty farm tracks and forest floors all the way back to HQ. Sunshine pastries, apfelschorles and morning coffees were the order of the final stop: Ortlieb’s nearest cafe…

Back to Heilsbronn. Still no sign of Hartmut. Back to Nuremburg … and finally back to Manchester, with a much greater insight and renewed respect for the 37-year-old German company. A brand with an interesting history, a strong authentic heritage, practical long-lasting product, employees that actually bikepack … and the enigmatic founder factor. What’s not to like about Ortlieb?

Any comments or questions, please free to use Disqus, below…

Words, Photos & Illustration

Stefan Amato

Tourers

Nils Amelinckx

Scot Easter

Peter Wöstmann

Volker Haug

Literature

©ORTLIEB Sportartikel GmbH

*Ortlieb UK is distributed by Lyon Equipment

** I tried to get a Singer™ pun in there, but failed

***I’m not a spy

All quotes from Ortlieb Literature, past and present